The advice of “always get 3 quotes” before hiring trades is often treated as a bidding war used to get a deal with the lowest price.

Here is 3 reasons why this approach can be catastrophic when it comes to hiring a metal roofing contractor.

1) The difference between a good metal roof and a bad one is substantial

There are many trades that have a narrow range of quality outcomes that they provide. To a certain degree, your plumbing is either built to code and functions or it doesn’t. Do the lights come on when you flick the switch? As long as your electrical is safety compliant, there isn’t a lot left to differentiate quality.

To a certain degree asphalt roofing is like this. The installation process is simple and standardized to a degree that many carpenters will even install shingles. The difference between an extremely good asphalt roof and a bad one is often not more than a few extra hours spent on the details.

This means that when hiring trades for shingle roofing, plumbing, electrical, and many other trades, as long as the contractor is credentialed and ethical, the lowest price can often be worth it.

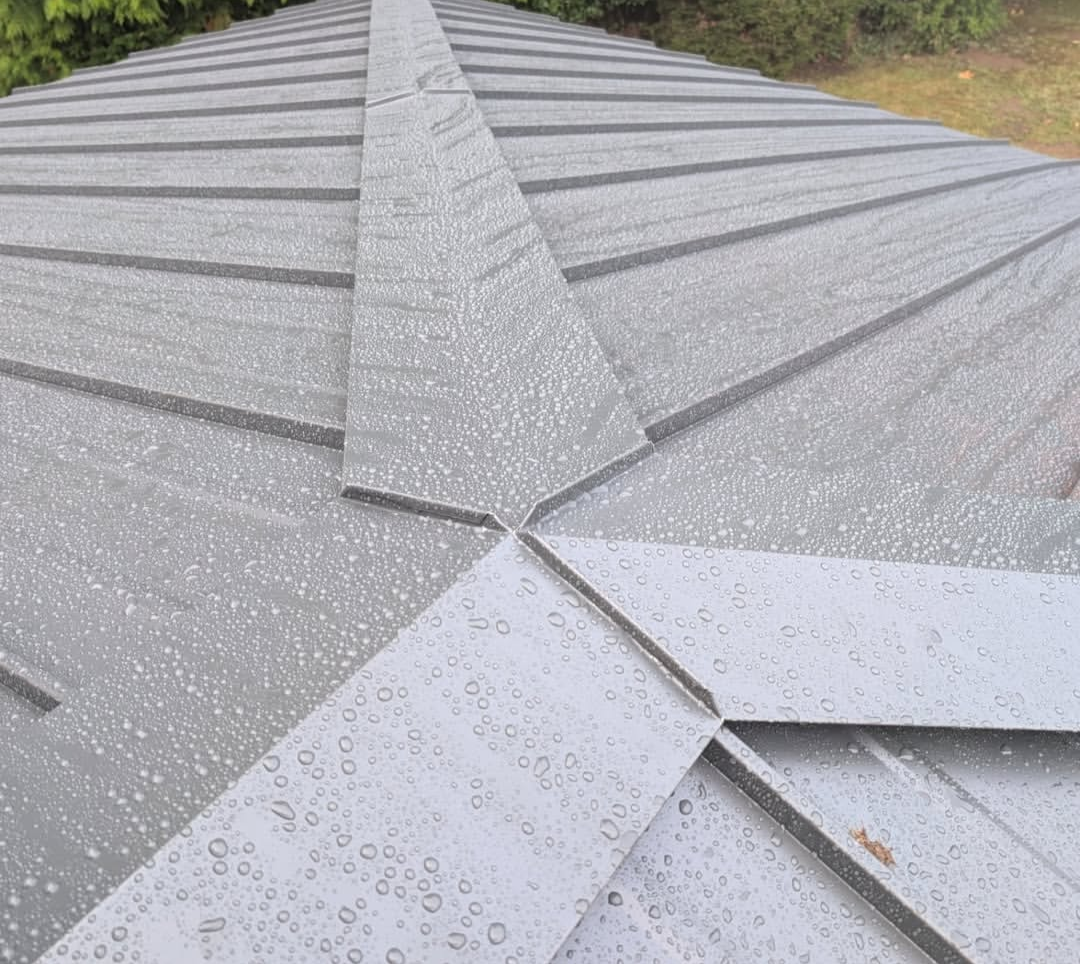

For metal roofing, the cheapest price is never worth it because the difference between a good installation and a bad one takes days worth of extra work. In some cases it can take twice as long as a cheap and dirty installation. These extra days spent in crafting the metal roof will increase its lifespan by 2-3x as we’ve seen in having repaired many metal roofs at the 15-20 year mark, far before the 50-60 year benchmark.

A tangible example of this is the use of exposed cladding screws on a metal roof will cut the time of installing ridge cap flashings in half, but the screws puncture the roof and rely on a grommet to seal the hole with a 15 year lifespan. The screws also pin the metal in a way that can highlight imperfections and worsen oil canning (rippling in the metal). So by spending more on a contractor who will then spend more time on your project, you effectively triple its lifespan.

2) The niched and highly technical skillset of metal roofing is rare

Sheet metal as a trade covers the large expanse of ducting, to shop fabrication, to wall cladding, to auto body, all of which are physically easier on the body. Good sheet metal guys often excel in those easier trades and rarely want to work at heights and be exposed to the harsh weather.

For that reason, unfortunately many people enter metal roofing without the technical skillset or attention to detail to pull off a quality metal roof.

On top of this, it takes anywhere from 3-10 times longer to install metal compared to asphalt for an experienced crew. Largely what you’re paying for when you buy a metal roof is the experience and time of the crew.

This means that it’s of the utmost importance that you find the needle in a haystack that is a quality metal crew. We know from experience in having hired many metal roofers that the good ones aren’t cheap.

3) If you do it right, you’ll only need to buy one metal roof in your lifetime

This is a short and powerful point that speaks for itself. We say that we install “roofs your great grandchildren will love.” The effects of the decision you make today will be felt 50 years from now, and in that frame of reference, it’s silly to prioritize cost over quality.

A good metal roof might cost 20% more today, but if it lasts 3x as long, it’s the economical decision.

The takeaway here is to screen your metal roofing contractor for quality as the deciding metric in the purchase of your roof.

You can do this by checking reviews and looking at the bidders experience in the industry. Ask if cladding screws will be used, and be prepared to take the higher bids in your search for a generational roof.

Leave A Comment